Lixiviación de indio con pirofosfato a partir de una jarosita industrial

DOI:

https://doi.org/10.36790/epistemus.v17i34.272Palabras clave:

Indio, Pirofosfato, Hidrometalurgia, LixiviaciónResumen

La jarosita es producida en la naturaleza en ambientes húmedos en presencia de sulfuros; además es producida en forma de precipitado en algunos procesos metalúrgicos como método de tratamiento de algunas soluciones para el control de hierro presente en las soluciones ácidas; el precipitado formado como jarosita tiene contenidos de algunos metales de interés como el oro, la plata, y el indio. En este trabajo se presenta el efecto del pH, concentración de pirofosfato y tiempo de lixiviación con la finalidad de recuperar el indio contenido en una jarosita industrial a temperatura ambiente

Descargas

Citas

. Alfantazi, A. M. and R. R. Moskalyk. 2003. Processing of indium: a review. Minerals Engineering 16(8): 687-694. http://dx.doi.org/10.1016/S0892-6875(03)00168-7 DOI: https://doi.org/10.1016/S0892-6875(03)00168-7

. Pradhan, D., Panda, S., & Sukla, L. 2017. Recent advances in indium metallurgy: A review. Mineral Processing and Extractive Metallurgy Review, 39, 167–180. http://dx.doi.org/10.1080/08827508.2017.1399887 DOI: https://doi.org/10.1080/08827508.2017.1399887

. Goldfarb, R. J. "Critical Metals Handbook (Gus Gunn, ed.). 2014. "Economic Geology 109(6): 1801-1802. http://dx.doi.org/10.2113/econgeo.109.6.1801 DOI: https://doi.org/10.2113/econgeo.109.6.1801

. E. M. Harper, , Goksin Kavlak, Lara Burmeister, Matthew J. Eckelman, Serkan Erbis, Vicente Sebastian Espinoza, Philip Nuss, T. E. Graedel. 2015. Criticality of the Geological Zinc, Tin, and Lead Family. Journal of Industrial Ecology, 19(4), 628-644.http://dx.doi.org/10.1111/jiec.12213 DOI: https://doi.org/10.1111/jiec.12213

. Humpston, G., & Jacobson, D. M. 2005. Solders and Their Metallurgy In Principles of Soldering (pp. 0): ASM International. http://dx.doi.org/10.31399/asm.tb.ps.t62440049 DOI: https://doi.org/10.31399/asm.tb.ps.9781627083522

. Nakamura, M., Yamaguchi, K., Kimoto, Y., Yasaki, Y., Kato, T., & Sugimoto, H. 2019. Cd-Free Cu(In,Ga)(Se,S)2 thin-film solar cell with record efficiency of 23.35%. IEEE Journal of Photovoltaics, 9, 1863-186 http://dx.doi.org/10.1109/JPHOTOV.2019.2937218 DOI: https://doi.org/10.1109/JPHOTOV.2019.2937218

. Too, S., Touzelbaev, M., Khan, M., Master, R., Diep, J., & Keok, K.-H. 2009. Indium Thermal Interface Material Development for Microprocessors. http://dx.doi.org/10.1109/STHERM.2009.4810762 DOI: https://doi.org/10.1109/STHERM.2009.4810762

. Zhang, L., Chen, X., Wan, F., Niu, Z., Wang, Y., Zhang, Q., & Chen, J. 2008. Enhanced Electrochemical Kinetics and Polysulfide Traps of Indium Nitride for Highly Stable Lithium–Sulfur Batteries. ACS Nano, 12(9), 9578-9586. http://dx.doi.org/10.1021/acsnano.8b05466 DOI: https://doi.org/10.1021/acsnano.8b05466

. N. J. Cook, Sundblad, K., Valkama, M., Nygård, R., Ciobanu, C. L., & Danyushevsky, L. 2011.Indium mineralisation in A-type granites in southeastern Finland: Insights into mineralogy and partitioning between coexisting minerals. Chemical Geology, 284(1), 62-73. http://dx.doi.org/10.1016/j.chemgeo.2011.02.006 DOI: https://doi.org/10.1016/j.chemgeo.2011.02.006

. Murakami, H., & Ishihara, S. 2013. Trace elements of Indium-bearing sphalerite from tin-polymetallic deposits in Bolivia, China and Japan: A femto-second LA-ICPMS study. Ore Geology Reviews, 53, 223-243, Enero 2013, http://dx.doi.org/10.1016/j.oregeorev.2013.01.010 DOI: https://doi.org/10.1016/j.oregeorev.2013.01.010

. Schwarz-Schampera. 2013. U. Indium. In Critical Metals Handbook. http://dx.doi.org/10.1002/9781118755341.ch9 DOI: https://doi.org/10.1002/9781118755341.ch9

. Groat, L. A., Jambor, J., & Pemberton, B. 2003. The crystal structure of argentojarosite, AgFe3(SO4)(2)(OH)(6). Canadian Mineralogist - CAN MINERALOG, 41, 921-928. http://dx.doi.org/10.2113/gscanmin.41.4.921 DOI: https://doi.org/10.2113/gscanmin.41.4.921

. Das, G. K., Acharya, S., Anand, S., & Das, R. P. 1996. Jarosites: A Review. Mineral Processing and Extractive Metallurgy Review, 16(3), 185-210. http://dx.doi.org/10.1080/08827509708914135 DOI: https://doi.org/10.1080/08827509708914135

. Wegscheider, S., Steinlechner, S., & Leuchtenmüller, M. 2016. Innovative Concept for the Recovery of Silver and Indium by a Combined Treatment of Jarosite and Electric Arc Furnace Dust. JOM, 69(2), 388-394. http://dx.doi.org/10.1007/s11837-016-2192-7 DOI: https://doi.org/10.1007/s11837-016-2192-7

. Kerolli–Mustafa, M., Fajković, H., Rončević, S., & Ćurković, L. 2015. Assessment of metal risks from different depths of jarosite tailing waste of Trepça Zinc Industry, Kosovo based on BCR procedure. Journal of Geochemical Exploration, 148, 161-168. http://dx.doi.org/10.1016/j.gexplo.2014.09.001 DOI: https://doi.org/10.1016/j.gexplo.2014.09.001

. Maihatchi Ahamed, A., Pons, M. N., Ricoux, Q., Issa, S., Goettmann, F., & Lapicque, F. 2021. New pathway for utilization of jarosite, an industrial waste of zinc hydrometallurgy. 170, 107030. http://dx.doi.org/10.1016/j.mineng.2021.107030 DOI: https://doi.org/10.1016/j.mineng.2021.107030

. Li, S.-q., Tang, M.-t., He, J., Yang, S.-h., Tang, C.-b., & Chen, Y.-m. 2006. Extraction of indium from indium-zinc concentrates. Transactions of Nonferrous Metals Society of China, 16(6), 1448-1454. http://dx.doi.org/10.1016/S1003-6326(07)60036-3 DOI: https://doi.org/10.1016/S1003-6326(07)60036-3

. Zhang, K., Wu, Y., Wang, W., Li, B., Zhang, Y., & Zuo, T. 2015. Recycling indium from waste LCDs: A review. Resources, Conservation and Recycling, 104, 276-290. http://dx.doi.org/10.1016/j.resconrec.2015.07.015 DOI: https://doi.org/10.1016/j.resconrec.2015.07.015

. Toache-Pérez, A. D., Lapidus, G. T., Bolarín-Miró, A. M., & De Jesús, F. S. 2022. Selective Leaching and Recovery of Er, Gd, Sn, and In from Liquid Crystal Display Screen Waste by Sono-Leaching Assisted by Magnetic Separation. ACS Omega, 7(36), 31897-31904. http://dx.doi.org/10.1021/acsomega.2c02729 DOI: https://doi.org/10.1021/acsomega.2c02729

. Ikotun, O. F., Marino, N., Kruger, P. E., Julve, M., & Doyle, R. P. 2010. Coordination complexes incorporating pyrophosphate: Structural overview and exploration of their diverse magnetic, catalytic and biological properties. Coordination Chemistry Reviews, 254(7), 890-915. http://dx.doi.org/10.1016/j.ccr.2009.12.015 DOI: https://doi.org/10.1016/j.ccr.2009.12.015

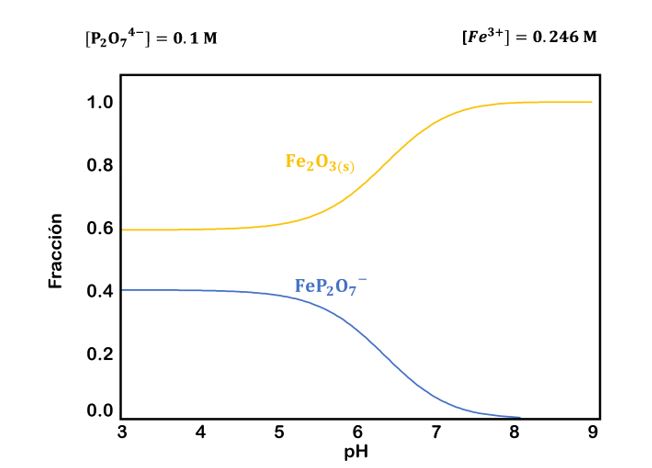

. Peter Linstrom. 2017. NIST Chemistry WebBook - SRD 69, National Institute of Standards and Technology, 2022

. Puigdomenech, I. 2004. Make equilibrium diagrams using sophisticated algorithms (MEDUSA), inorganic chemistry. Stockholm, Sweden

Publicado

Cómo citar

Número

Sección

Licencia

Derechos de autor 2023 EPISTEMUS

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-CompartirIgual 4.0.

La revista adquiere los derechos patrimoniales de los artículos sólo para difusión sin ningún fin de lucro, sin menoscabo de los propios derechos de autoría.

Los autores son los legítimos titulares de los derechos de propiedad intelectual de sus respectivos artículos, y en tal calidad, al enviar sus textos expresan su deseo de colaborar con la Revista Epistemus, editada semestralmente por la Universidad de Sonora.

Por lo anterior, de manera libre, voluntaria y a título gratuito, una vez aceptado el artículo para su publicación, ceden sus derechos a la Universidad de Sonora para que la Universidad de Sonora edite, publique, distribuya y ponga a disposición a través de intranets, internet o CD dicha obra, sin limitación alguna de forma o tiempo, siempre y cuando sea sin fines de lucro y con la obligación expresa de respetar y mencionar el crédito que corresponde a los autores en cualquier utilización que se haga del mismo.

Queda entendido que esta autorización no es una cesión o transmisión de alguno de sus derechos patrimoniales en favor de la mencionada institución. La UniSon le garantiza el derecho de reproducir la contribución por cualquier medio en el cual usted sea el autor, sujeto a que se otorgue el crédito correspondiente a la publicación original de la contribución en Epistemus.

Salvo indicación contraria, todos los contenidos de la edición electrónica se distribuyen bajo una licencia de uso y Attribution-NonCommercial-ShareAlike 4.0 International (CC BY-NC-SA 4.0) Puede consultar desde aquí la versión informativa y el texto legal de la licencia. Esta circunstancia ha de hacerse constar expresamente de esta forma cuando sea necesario.