Quantification of Wear in Drill Bits Using the Pure Abrasion and Isotropic Wear Model

DOI:

https://doi.org/10.36790/epistemus.v16i32.184Keywords:

Mining, Drilling, Drill beat wear, Isotropic ModelAbstract

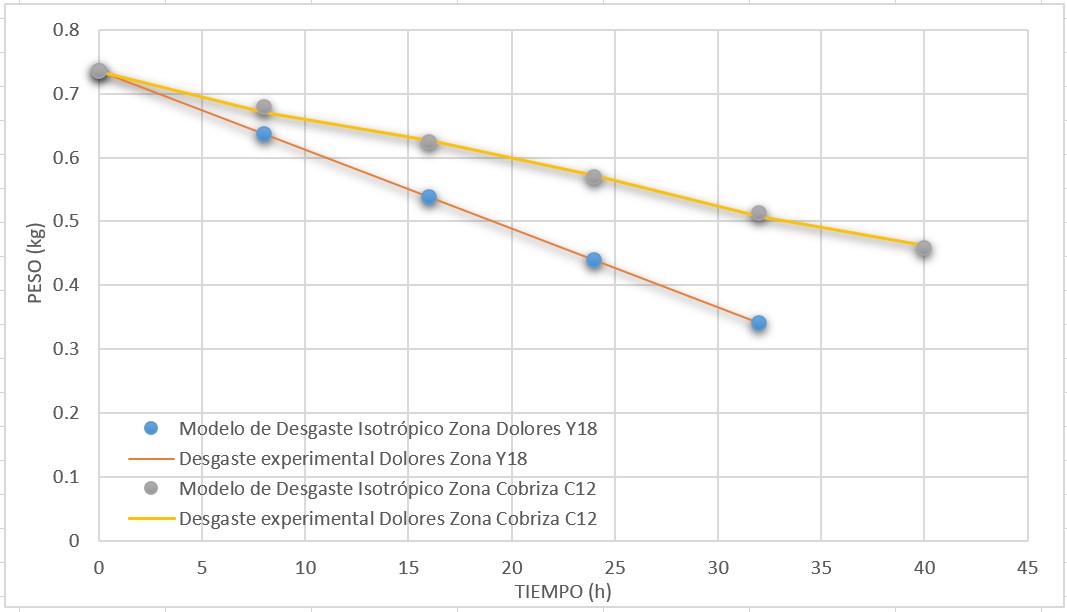

Geological wear factors in a hole are currently being studied since the type of soil, as well as the lack of knowledge of its composition, have a significant impact on the wear of diamond drill bits. Abrasive materials in rocks and valuable metal occluded aggregates reduce bit life. In the present work, drill bits with diamond embedded in the matrix are tested in two deposits, Zona Dolores Y18 and Zona Cobriza C12, where the semi-fractured granodiorite intrusive is variable in both deposits, for such evaluation the model of pure abrasion and isotropic wear was resolved. This model showed that the variation in the amount of semi-fractured granodiorite impacts the performance of the drill bits with a drilling of up to 20m, which represents a reduction of up to 8 hours in the drilling work.

Downloads

References

Menacho, J., Concha, F., Mathematical model of ball wear in grinding mills I. Zero-order wear rate, Powder Technology, Volume 47, Issue 1, 1986, Pages 87-96. https://doi.org/10.1016/0032-5910(86)80013-4 DOI: https://doi.org/10.1016/0032-5910(86)80013-4

González, J. (2013), Análisis estructural de la Sierra del Fraile y sistemas de mineralización del distrito minero La Paz, S.L.P, Tesis de Maestría, pp 125-135. https://repositorioinstitucional.uaslp.mx/xmlui/handle/i/4087

G. Rosales-Marín, J. Andrade, G. Alvarado, J.A. Delgadillo, E.T. Tuzcu, Study of lifter wear and breakage rates for different lifter geometries in tumbling mill: Experimental and simulation analysis using population balance model, Minerals Engineering, Volume 141, 2019. https://doi.org/10.1016/j.mineng.2019.105857. DOI: https://doi.org/10.1016/j.mineng.2019.105857

Changhua Xie, Yongzhi Zhao, (2021), Investigation of the ball wear in a planetary mill by DEM simulation, Powder Technology, 117057. https://doi.org/10.1016/j.powtec.2021.117057 DOI: https://doi.org/10.1016/j.powtec.2021.117057

Gangopadhyay A, Moore J. (1985), The role of abrasion and corrosion in grinding media wear. Wear, vol. 104, pp 49-64. https://doi.org/10.1016/0043-1648(85)90245-5 DOI: https://doi.org/10.1016/0043-1648(85)90245-5

Sepulveda, J. E. (2004), Methodologies for the evaluation of grinding media consumption rates at full plant scale, Minerals Engineering, vol 17, pp 1269–1279. https://doi.org/10.1016/j.mineng.2004.08.007 DOI: https://doi.org/10.1016/j.mineng.2004.08.007

F. Knoop, C.G. Peters and W.B. Emerson, “A Sensitive Pyramidal-Diamond Tool for Indentation Measurements,” Journal of Research of the National Bureau of Standards, V. 23 nº 1, julio de 1939, Research Paper RP1220, Pp. 39–6. https://archive.org/details/jresv23n1p39/mode/2up DOI: https://doi.org/10.6028/jres.023.022

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 EPISTEMUS

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

The magazine acquires the patrimonial rights of the articles only for diffusion without any purpose of profit, without diminishing the own rights of authorship.

The authors are the legitimate owners of the intellectual property rights of their respective articles, and in such quality, by sending their texts they express their desire to collaborate with the Epistemus Magazine, published biannually by the University of Sonora.

Therefore, freely, voluntarily and free of charge, once accepted the article for publication, they give their rights to the University of Sonora for the University of Sonora to edit, publish, distribute and make available through intranets, Internet or CD said work, without any limitation of form or time, as long as it is non-profit and with the express obligation to respect and mention the credit that corresponds to the authors in any use that is made of it.

It is understood that this authorization is not an assignment or transmission of any of your economic rights in favor of the said institution. The University of Sonora guarantees the right to reproduce the contribution by any means in which you are the author, subject to the credit being granted corresponding to the original publication of the contribution in Epistemus.

Unless otherwise indicated, all the contents of the electronic edition are distributed under a license for use and Creative Commons — Attribution-NonCommercial-ShareAlike 4.0 International — (CC BY-NC-SA 4.0) You can consult here the informative version and the legal text of the license. This circumstance must be expressly stated in this way when necessary.

The names and email addresses entered in this journal will be used exclusively for the purposes established in it and will not be provided to third parties or for their use for other purposes.