Indium Leaching with Pyrophosphate from Industrial Jarosite

DOI:

https://doi.org/10.36790/epistemus.v17i34.272Keywords:

Indium, Pyrophosphate, Hydrometallurgy, LeachingAbstract

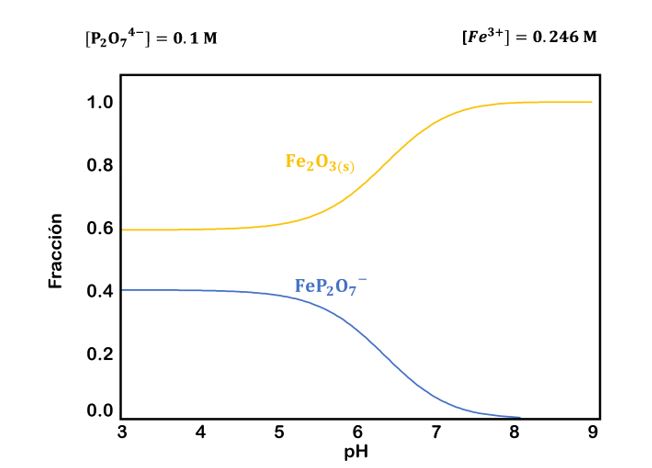

Jarosite is naturally produced in humid environments in the presence of sulfides; It is also produced in the form of a precipitate in some metallurgical processes as a treatment method for some solutions to control the iron present in acid solutions; the precipitate formed as jarosite has contents of some metals of interest such as gold, silver, and indium. This work presents the effect of pH, pyrophosphate concentration, and leaching time in order to recover the indium contained in industrial jarosite at room temperature

Downloads

References

. Alfantazi, A. M. and R. R. Moskalyk. 2003. Processing of indium: a review. Minerals Engineering 16(8): 687-694. http://dx.doi.org/10.1016/S0892-6875(03)00168-7 DOI: https://doi.org/10.1016/S0892-6875(03)00168-7

. Pradhan, D., Panda, S., & Sukla, L. 2017. Recent advances in indium metallurgy: A review. Mineral Processing and Extractive Metallurgy Review, 39, 167–180. http://dx.doi.org/10.1080/08827508.2017.1399887 DOI: https://doi.org/10.1080/08827508.2017.1399887

. Goldfarb, R. J. "Critical Metals Handbook (Gus Gunn, ed.). 2014. "Economic Geology 109(6): 1801-1802. http://dx.doi.org/10.2113/econgeo.109.6.1801 DOI: https://doi.org/10.2113/econgeo.109.6.1801

. E. M. Harper, , Goksin Kavlak, Lara Burmeister, Matthew J. Eckelman, Serkan Erbis, Vicente Sebastian Espinoza, Philip Nuss, T. E. Graedel. 2015. Criticality of the Geological Zinc, Tin, and Lead Family. Journal of Industrial Ecology, 19(4), 628-644.http://dx.doi.org/10.1111/jiec.12213 DOI: https://doi.org/10.1111/jiec.12213

. Humpston, G., & Jacobson, D. M. 2005. Solders and Their Metallurgy In Principles of Soldering (pp. 0): ASM International. http://dx.doi.org/10.31399/asm.tb.ps.t62440049 DOI: https://doi.org/10.31399/asm.tb.ps.9781627083522

. Nakamura, M., Yamaguchi, K., Kimoto, Y., Yasaki, Y., Kato, T., & Sugimoto, H. 2019. Cd-Free Cu(In,Ga)(Se,S)2 thin-film solar cell with record efficiency of 23.35%. IEEE Journal of Photovoltaics, 9, 1863-186 http://dx.doi.org/10.1109/JPHOTOV.2019.2937218 DOI: https://doi.org/10.1109/JPHOTOV.2019.2937218

. Too, S., Touzelbaev, M., Khan, M., Master, R., Diep, J., & Keok, K.-H. 2009. Indium Thermal Interface Material Development for Microprocessors. http://dx.doi.org/10.1109/STHERM.2009.4810762 DOI: https://doi.org/10.1109/STHERM.2009.4810762

. Zhang, L., Chen, X., Wan, F., Niu, Z., Wang, Y., Zhang, Q., & Chen, J. 2008. Enhanced Electrochemical Kinetics and Polysulfide Traps of Indium Nitride for Highly Stable Lithium–Sulfur Batteries. ACS Nano, 12(9), 9578-9586. http://dx.doi.org/10.1021/acsnano.8b05466 DOI: https://doi.org/10.1021/acsnano.8b05466

. N. J. Cook, Sundblad, K., Valkama, M., Nygård, R., Ciobanu, C. L., & Danyushevsky, L. 2011.Indium mineralisation in A-type granites in southeastern Finland: Insights into mineralogy and partitioning between coexisting minerals. Chemical Geology, 284(1), 62-73. http://dx.doi.org/10.1016/j.chemgeo.2011.02.006 DOI: https://doi.org/10.1016/j.chemgeo.2011.02.006

. Murakami, H., & Ishihara, S. 2013. Trace elements of Indium-bearing sphalerite from tin-polymetallic deposits in Bolivia, China and Japan: A femto-second LA-ICPMS study. Ore Geology Reviews, 53, 223-243, Enero 2013, http://dx.doi.org/10.1016/j.oregeorev.2013.01.010 DOI: https://doi.org/10.1016/j.oregeorev.2013.01.010

. Schwarz-Schampera. 2013. U. Indium. In Critical Metals Handbook. http://dx.doi.org/10.1002/9781118755341.ch9 DOI: https://doi.org/10.1002/9781118755341.ch9

. Groat, L. A., Jambor, J., & Pemberton, B. 2003. The crystal structure of argentojarosite, AgFe3(SO4)(2)(OH)(6). Canadian Mineralogist - CAN MINERALOG, 41, 921-928. http://dx.doi.org/10.2113/gscanmin.41.4.921 DOI: https://doi.org/10.2113/gscanmin.41.4.921

. Das, G. K., Acharya, S., Anand, S., & Das, R. P. 1996. Jarosites: A Review. Mineral Processing and Extractive Metallurgy Review, 16(3), 185-210. http://dx.doi.org/10.1080/08827509708914135 DOI: https://doi.org/10.1080/08827509708914135

. Wegscheider, S., Steinlechner, S., & Leuchtenmüller, M. 2016. Innovative Concept for the Recovery of Silver and Indium by a Combined Treatment of Jarosite and Electric Arc Furnace Dust. JOM, 69(2), 388-394. http://dx.doi.org/10.1007/s11837-016-2192-7 DOI: https://doi.org/10.1007/s11837-016-2192-7

. Kerolli–Mustafa, M., Fajković, H., Rončević, S., & Ćurković, L. 2015. Assessment of metal risks from different depths of jarosite tailing waste of Trepça Zinc Industry, Kosovo based on BCR procedure. Journal of Geochemical Exploration, 148, 161-168. http://dx.doi.org/10.1016/j.gexplo.2014.09.001 DOI: https://doi.org/10.1016/j.gexplo.2014.09.001

. Maihatchi Ahamed, A., Pons, M. N., Ricoux, Q., Issa, S., Goettmann, F., & Lapicque, F. 2021. New pathway for utilization of jarosite, an industrial waste of zinc hydrometallurgy. 170, 107030. http://dx.doi.org/10.1016/j.mineng.2021.107030 DOI: https://doi.org/10.1016/j.mineng.2021.107030

. Li, S.-q., Tang, M.-t., He, J., Yang, S.-h., Tang, C.-b., & Chen, Y.-m. 2006. Extraction of indium from indium-zinc concentrates. Transactions of Nonferrous Metals Society of China, 16(6), 1448-1454. http://dx.doi.org/10.1016/S1003-6326(07)60036-3 DOI: https://doi.org/10.1016/S1003-6326(07)60036-3

. Zhang, K., Wu, Y., Wang, W., Li, B., Zhang, Y., & Zuo, T. 2015. Recycling indium from waste LCDs: A review. Resources, Conservation and Recycling, 104, 276-290. http://dx.doi.org/10.1016/j.resconrec.2015.07.015 DOI: https://doi.org/10.1016/j.resconrec.2015.07.015

. Toache-Pérez, A. D., Lapidus, G. T., Bolarín-Miró, A. M., & De Jesús, F. S. 2022. Selective Leaching and Recovery of Er, Gd, Sn, and In from Liquid Crystal Display Screen Waste by Sono-Leaching Assisted by Magnetic Separation. ACS Omega, 7(36), 31897-31904. http://dx.doi.org/10.1021/acsomega.2c02729 DOI: https://doi.org/10.1021/acsomega.2c02729

. Ikotun, O. F., Marino, N., Kruger, P. E., Julve, M., & Doyle, R. P. 2010. Coordination complexes incorporating pyrophosphate: Structural overview and exploration of their diverse magnetic, catalytic and biological properties. Coordination Chemistry Reviews, 254(7), 890-915. http://dx.doi.org/10.1016/j.ccr.2009.12.015 DOI: https://doi.org/10.1016/j.ccr.2009.12.015

. Peter Linstrom. 2017. NIST Chemistry WebBook - SRD 69, National Institute of Standards and Technology, 2022

. Puigdomenech, I. 2004. Make equilibrium diagrams using sophisticated algorithms (MEDUSA), inorganic chemistry. Stockholm, Sweden

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 EPISTEMUS

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

The magazine acquires the patrimonial rights of the articles only for diffusion without any purpose of profit, without diminishing the own rights of authorship.

The authors are the legitimate owners of the intellectual property rights of their respective articles, and in such quality, by sending their texts they express their desire to collaborate with the Epistemus Magazine, published biannually by the University of Sonora.

Therefore, freely, voluntarily and free of charge, once accepted the article for publication, they give their rights to the University of Sonora for the University of Sonora to edit, publish, distribute and make available through intranets, Internet or CD said work, without any limitation of form or time, as long as it is non-profit and with the express obligation to respect and mention the credit that corresponds to the authors in any use that is made of it.

It is understood that this authorization is not an assignment or transmission of any of your economic rights in favor of the said institution. The University of Sonora guarantees the right to reproduce the contribution by any means in which you are the author, subject to the credit being granted corresponding to the original publication of the contribution in Epistemus.

Unless otherwise indicated, all the contents of the electronic edition are distributed under a license for use and Creative Commons — Attribution-NonCommercial-ShareAlike 4.0 International — (CC BY-NC-SA 4.0) You can consult here the informative version and the legal text of the license. This circumstance must be expressly stated in this way when necessary.

The names and email addresses entered in this journal will be used exclusively for the purposes established in it and will not be provided to third parties or for their use for other purposes.