Simulations of Mechanical Stress in Materials for Engineering

DOI:

https://doi.org/10.36790/epistemus.v18i36.314Keywords:

SolidWorks, Stress, Mechanical stressAbstract

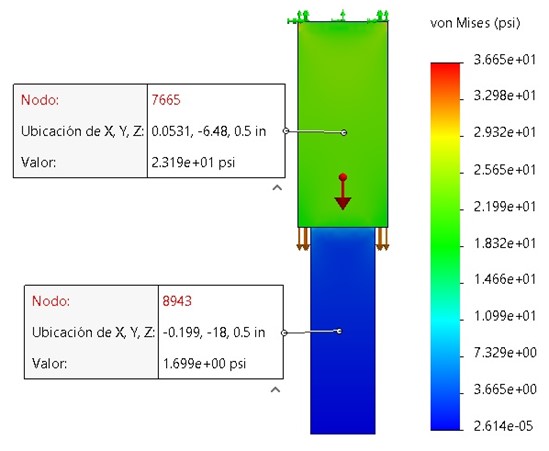

The work developed in this article corresponds to teaching engineering students how, through the use of a simulation with SolidWorks® software, it is possible to obtain the same results as doing a mathematical analysis of mechanical stresses in materials. The article explains a series of steps to follow in this software to obtain stress analysis results. First, the mathematical analysis in a type of material (two metal plates) is briefly explained. Then, the same results are obtained using the software, as by understanding the fundamental concepts of stresses, the student will be able to comprehend and predict the results generated by SolidWorks® without studying the mathematics involved in the analysis of the material in-depth.

Downloads

References

(2010). Mecánica de materiales (No. TA405. B43 1994.). Mc Graw Hill.

Hancock, J. W., & Mackenzie, A. C. (1976). On the mechanisms of ductile failure in high-strength steels subjected to multi-axial stress-states. Journal of the Mechanics and Physics of Solids, 24(2-3), 147-160. DOI: https://doi.org/10.1016/0022-5096(76)90024-7 DOI: https://doi.org/10.1016/0022-5096(76)90024-7

Salehinia, I., Shao, S., Wang, J., & Zbib, H. M. (2014). Plastic deformation of metal/ceramic nanolayered composites. Jom, 66, 2078-2085. DOI: https://doi.org/10.1007/s11837-014-1132-7 DOI: https://doi.org/10.1007/s11837-014-1132-7

Karuppasamy, K. S. K., Balaji, P. S., & Sahoo, N. (2020). Introduction to Stress-Strain Relationship and Its Measurement Techniques. In Applications and Techniques for Experimental Stress Analysis (pp. 22-38). IGI Global. DOI: 10.4018/978-1-7998-1690-4.ch002 DOI: https://doi.org/10.4018/978-1-7998-1690-4.ch002

Tu, S., Ren, X., He, J., & Zhang, Z. (2020). Stress–strain curves of metallic materials and post‐necking strain hardening characterization: A review. Fatigue & Fracture of Engineering Materials & Structures, 43(1), 3-19. DOI: https://doi.org/10.1111/ffe.13134 DOI: https://doi.org/10.1111/ffe.13134

Nemati, K. M., Monteiro, P. J., & Scrivener, K. L. (1998). Analysis of compressive stress-induced cracks in concrete. ACI Materials Journal, 95, 617-630. DOI: https://doi.org/10.14359/404

Nakamitsu, M., Oyama, K., Imai, H., Fujii, S., & Oaki, Y. (2021). Ultrahigh‐sensitive compression‐stress sensor using integrated stimuli‐responsive materials. Advanced Materials, 33(14), 2008755. DOI: https://doi.org/10.1002/adma.202008755 DOI: https://doi.org/10.1002/adma.202008755

Naughton, J. W., & Sheplak, M. (2002). Modern developments in shear-stress measurement. Progress in Aerospace Sciences, 38(6-7), 515-570. DOI: https://doi.org/10.1016/S0376-0421(02)00031-3 DOI: https://doi.org/10.1016/S0376-0421(02)00031-3

Fu, P., & Dafalias, Y. F. (2011). Study of anisotropic shear strength of granular materials using DEM simulation. International Journal for Numerical and Analytical Methods in Geomechanics, 35(10), 1098-1126. DOI: https://doi.org/10.1002/nag.945 DOI: https://doi.org/10.1002/nag.945

Towle, L. C., & Riecker, R. E. (1968). Empirical relationship between shear strength, pressure, and temperature-II. Applied Physics Letters, 13(5), 159-161. DOI: https://doi.org/10.1063/1.1754828 DOI: https://doi.org/10.1063/1.1652552

Varghese, T., Ophir, J., & Krouskop, T. A. (2000). Nonlinear stress-strain relationships in tissue and their effect on the contrast-to-noise ratio in elastograms. Ultrasound in medicine & biology, 26(5), 839-851. DOI: https://doi.org/10.1016/S0301-5629(00)00199-X DOI: https://doi.org/10.1016/S0301-5629(00)00199-X

Amijima, S., & Adachi, T. (1979). Nonlinear stress-strain response of laminated composites. Journal of composite materials, 13(3), 206-218. DOI: https://doi.org/10.1177/0021998379013003 DOI: https://doi.org/10.1177/002199837901300303

Rossini, N. S., Dassisti, M., Benyounis, K. Y., & Olabi, A. G. (2012). Methods of measuring residual stresses in components. Materials & Design, 35, 572-588. DOI: https://doi.org/10.1016/j.matdes.2011.08.022 DOI: https://doi.org/10.1016/j.matdes.2011.08.022

Parlevliet, P. P., Bersee, H. E., & Beukers, A. (2007). Residual stresses in thermoplastic composites—A study of the literature—Part I: Formation of residual stresses. Composites Part A: Applied Science and Manufacturing, 37(11), 1847-1857. DOI: https://doi.org/10.1016/j.compositesa.2006.12.005 DOI: https://doi.org/10.1016/j.compositesa.2005.12.025

Suárez, J. C., Remartınez, B., Menéndez, J. M., Güemes, A., & Molleda, F. (2003). Optical fibre sensors for monitoring of welding residual stresses. Journal of materials processing technology, 143, 316-320. DOI: https://doi.org/10.1016/S0924-0136(03)00481-3 DOI: https://doi.org/10.1016/S0924-0136(03)00481-3

Sanderson, R. M., & Shen, Y. C. (2010). Measurement of residual stress using laser-generated ultrasound. International journal of pressure vessels and piping, 87(12), 762-765. DOI: https://doi.org/10.1016/j.ijpvp.2010.10.001 DOI: https://doi.org/10.1016/j.ijpvp.2010.10.001

Guo, L. C., & Noda, N. (2010). An analytical method for thermal stresses of a functionally graded material cylindrical shell under a thermal shock. Acta Mechanica, 214(1-2), 71-78. DOI: https://doi.org/10.1007/s00707-010-0315-8 DOI: https://doi.org/10.1007/s00707-010-0315-8

Reddy, J. N., & Chin, C. D. (1998). Thermomechanical analysis of functionally graded cylinders and plates. Journal of thermal Stresses, 21(6), 593-626. DOI: https://doi.org/10.1080/01495739808956165 DOI: https://doi.org/10.1080/01495739808956165

Lisiak-Myszke, M., Marciniak, D., Bieliński, M., Sobczak, H., Garbacewicz, Ł., & Drogoszewska, B. (2020). Application of finite element analysis in oral and maxillofacial surgery—A literature review. Materials, 13(14), 3063. DOI: https://doi.org/10.3390/ma13143063 DOI: https://doi.org/10.3390/ma13143063

Chandrupatla, T. (2004). Finite Element Analysis for Engineering & Tech. Universities Press.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 EPISTEMUS

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

The magazine acquires the patrimonial rights of the articles only for diffusion without any purpose of profit, without diminishing the own rights of authorship.

The authors are the legitimate owners of the intellectual property rights of their respective articles, and in such quality, by sending their texts they express their desire to collaborate with the Epistemus Magazine, published biannually by the University of Sonora.

Therefore, freely, voluntarily and free of charge, once accepted the article for publication, they give their rights to the University of Sonora for the University of Sonora to edit, publish, distribute and make available through intranets, Internet or CD said work, without any limitation of form or time, as long as it is non-profit and with the express obligation to respect and mention the credit that corresponds to the authors in any use that is made of it.

It is understood that this authorization is not an assignment or transmission of any of your economic rights in favor of the said institution. The University of Sonora guarantees the right to reproduce the contribution by any means in which you are the author, subject to the credit being granted corresponding to the original publication of the contribution in Epistemus.

Unless otherwise indicated, all the contents of the electronic edition are distributed under a license for use and Creative Commons — Attribution-NonCommercial-ShareAlike 4.0 International — (CC BY-NC-SA 4.0) You can consult here the informative version and the legal text of the license. This circumstance must be expressly stated in this way when necessary.

The names and email addresses entered in this journal will be used exclusively for the purposes established in it and will not be provided to third parties or for their use for other purposes.