The Zinc Hydrometallurgy: a Sustainable Solution for Mineral Concentrates and Mining Waste

DOI:

https://doi.org/10.36790/epistemus.v19i38.320Keywords:

Mine waste, Zinc, Circular economy, Hydrometallurgy, SustainabilityAbstract

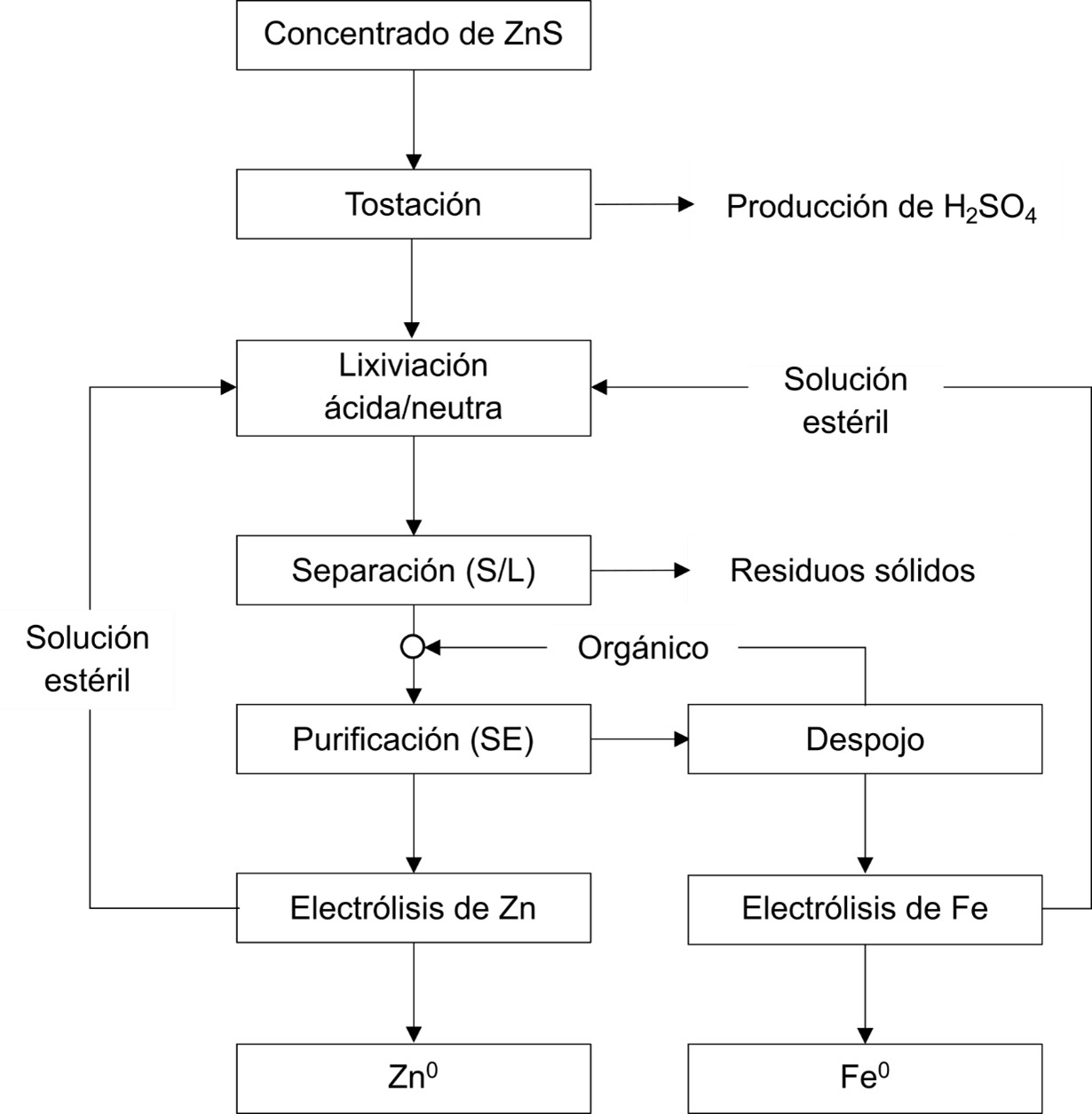

Zinc is a metal with various industrial applications that can be obtained through hydrometallurgical and pyrometallurgical processes. This review discusses the advances in the sustainable production of this metal. This approach involves the adoption of practices and processes that minimize environmental impact and promote the responsible use of resources. The various industrial applications of zinc and projected future demand are also explored. In addition, the extraction of zinc from secondary sources such as used batteries, electronic scrap, zinc alloys, among others, is reviewed. These processes introduce the concept of urban mining, which promotes the transition towards a circular economy. Recycling proves to be an economically viable activity and is also considered a way to reduce the volume of material sent to tailing dams.

Downloads

References

M. Pais and P. Rao, “An Up-to-Date Review on Industrially Significant Inhibitors for Corrosion Control of Zinc,” J. Bio. Tribo. Corrosion, vol. 7, no. 3, 2021, DOI: https://doi:10.1007/s40735-021-00556-x. DOI: https://doi.org/10.1007/s40735-021-00556-x

H. Kania and M. Saternus, “Evaluation and Current State of Primary and Secondary Zinc Production—A Review”. Appl. Sci., vol. 13, no. 3, p. 2003, 2023. DOI: https://doi:10.3390/app13032003. DOI: https://doi.org/10.3390/app13032003

“Home" | ZINC. International Zinc Association. Home | ZINC. International Zinc Association. Accessed: June 7, 2023. [Online]. Available: https://www.zinc.org/

R.J. Sinclair. The Extractive Metallurgy of Zinc. Spectrum Series. The Australasian Institute of Mining and Metallurgy, 2005.

M. K. Jha, V. Kumar and R. J. Singh, “Review of hydrometallurgical recovery of zinc from industrial wastes”, Resources, Conservation Recycling, vol. 33, no. 1, pp. 1–22, 2001. DOI: https://doi:10.1016/s0921-3449(00)00095-1. DOI: https://doi.org/10.1016/S0921-3449(00)00095-1

E. C. I. Hammerbeck and A. T. M. Mehliss. In: Ore Deposits of the Republic of South Africa (eds.), pp. 461. Pretoria, South Africa: Department of Mining and the Geological Survey of South Africa, The Government Printer, 1976.

A. Maihatchi Ahamed, M. N. Pons, Q. Ricoux, S. Issa, F. Goettmann and F. Lapicque, “New pathway for utilization of jarosite, an industrial waste of zinc hydrometallurgy”, Minerals Eng., vol. 170, p. 107030, 2021. DOI: https://doi:10.1016/j.mineng.2021.107030. DOI: https://doi.org/10.1016/j.mineng.2021.107030

V. Masloboev, S. Seleznev, A. Svetlov and D. Makarov, “Hydrometallurgical Processing of Low-Grade Sulfide Ore and Mine Waste in the Arctic Regions: Perspectives and Challenges”, Minerals, vol. 8, no. 10, p. 436, 2018. DOI: https://doi:10.3390/min8100436. DOI: https://doi.org/10.3390/min8100436

M. Shamsuddin, Physical Chemistry of Metallurgical Processes, Second Edition. Cham: Springer International Publishing, 2021. DOI: https://doi:10.1007/978-3-030-58069-8. DOI: https://doi.org/10.1007/978-3-030-58069-8

B. Sun, C. Yang, H. Zhu, Y. Li and W. Gui, “Modeling, optimization, and control of solution purification process in zinc hydrometallurgy”, IEEE/CAA J. Automatica Sinica, vol. 5, no. 2, pp. 564–576, 2018. DOI: https://doi:10.1109/jas.2017.7510844. DOI: https://doi.org/10.1109/JAS.2017.7510844

A. B. Pérez, A. Ballester and L. F Verdeja. Metalurgia extractiva, vol. II. Síntesis, 2000.

F. Habashi. Handbook of Extractive Metallurgy, vol. II and III. Wiley – VCH, 1997.

L. G. Atanasova, “Exergy analysis of the process of regeneration of spent sulphuric acid by WSA technology”, Int. J. Exergy, vol. 24, no. 1, p. 57, 2017. DOI: https://doi:10.1504/ijex.2017.086860. DOI: https://doi.org/10.1504/IJEX.2017.086860

M. R. Zaker, C. Fauteux-Lefebvre and J. Thibault, “Modelling and Multi-Objective Optimization of the Sulphur Dioxide Oxidation Process”, Processes, vol. 9, no. 6, p. 1072, 2021. DOI: https://doi:10.3390/pr9061072. DOI: https://doi.org/10.3390/pr9061072

“Pollution and Pollution Prevention”, Handbook of Pollution Prevention and Cleaner Production: Best Practices in the Agrochemical Industry. Elsevier, 2011, pp. 25–79. DOI: https://doi:10.1016/b978-1-4377-7825-0.00002-9. DOI: https://doi.org/10.1016/B978-1-4377-7825-0.00002-9

J. E. Dutrizac, “The Behaviour of the Lanthanide Elements During Jarosite Precipitation”, Electrometallurgy and Environmental Hydrometallurgy. Hoboken, NJ, USA: John Wiley & Sons, Inc., 2013, pp. 1755–1771. DOI: https://doi:10.1002/9781118804407.ch51. DOI: https://doi.org/10.1002/9781118804407.ch51

X. Zhang, J. Tian, H. Han, W. Sun, Y. Hu, T. L. Wang, Y. Yang, X. Cao and H. Tang, “Arsenic removal from arsenic-containing copper and cobalt slag using alkaline leaching technology and MgNH4AsO4 precipitation”, Separation Purification Technol., vol. 238, p. 116422, May 2020. DOI: https://doi:10.1016/j.seppur.2019.116422. DOI: https://doi.org/10.1016/j.seppur.2019.116422

F. Cardarelli, Materials Handbook. Cham: Springer International Publishing, 2018. DOI: https://doi:10.1007/978-3-319-38925-7. DOI: https://doi.org/10.1007/978-3-319-38925-7

L. Hoeber and S. Steinlechner, “A comprehensive review of processing strategies for iron precipitation residues from zinc hydrometallurgy”, Cleaner Eng. Techno., vol. 4, p. 100214, Oct. 2021. DOI: https://doi:10.1016/j.clet.2021.100214. DOI: https://doi.org/10.1016/j.clet.2021.100214

W. Wang, T. Yuan, R. Li, X. Zhu, H. Li, W. Lin, L. Li and D. Zheng, “Electrochemical corrosion behaviors of Pb-Ag anodes by electric current pulse assisted casting”, J. Electroanalytical Chemistry, vol. 847, p. 113250, Aug. 2019. DOI: https://doi:10.1016/j.jelechem.2019.113250. DOI: https://doi.org/10.1016/j.jelechem.2019.113250

A. C. Scott, R. M. Pitblado, G. W. Barton and A. R. Ault, “Experimental determination of the factors affecting zinc electrowinning efficiency”, J. Appl. Electrochemistry, vol. 18, no. 1, pp. 120–127, Jan. 1988. DOI: https://doi:10.1007/bf01016215. DOI: https://doi.org/10.1007/BF01016215

N. Sorour, W. Zhang, G. Gabra, E. Ghali and G. Houlachi, “Electrochemical studies of ionic liquid additives during the zinc electrowinning process”, Hydrometallurgy, vol. 157, pp. 261–269, Oct. 2015. DOI: https://doi:10.1016/j.hydromet.2015.09.003. DOI: https://doi.org/10.1016/j.hydromet.2015.09.003

G. T. Lapidus, “Minimizing the Hydro in Hydrometallurgy”, The Minerals, Metals & Materials Series. Cham: Springer International Publishing, 2018, pp. 1193–1201. DOI: https://doi:10.1007/978-3-319-95022-8_96. DOI: https://doi.org/10.1007/978-3-319-95022-8_96

M. Nicol, N. Welham and G. Senanayake, “Solvent extraction”, Hydrometallurgy. Elsevier, 2022, pp. 117–170. DOI: https://doi:10.1016/b978-0-323-99214-5.00007-3. DOI: https://doi.org/10.1016/B978-0-323-99214-5.00007-3

F. Khanramaki, A.R. Keshtkar. “Optimization of thorium solvent extraction process from feed solution with Cyanex 272 by response surface methodology (RSM)”. Sci Rep 14, 2024. DOI: https://doi.org/10.1038/s41598-024-66091-0 DOI: https://doi.org/10.1038/s41598-024-66091-0

P. Tahmasebizadeh, S. Javanshir, “Solvent extraction of zinc from a bioleaching solution by modification of D2EHPA: optimization and thermodynamic studies”. JME 12(1), 2021, pp. 253–269.

A. Sokolov, D. Valeev, A. Kasikov. “Solvent Extraction of Iron(III) from Al Chloride Solution of Bauxite HCl Leaching by Mixture of Aliphatic Alcohol and Ketone”. Metals, vol 11, no. 2, 2021. DOI: https://doi.org/10.3390/met11020321 DOI: https://doi.org/10.3390/met11020321

J. Roman, S. Mišković. “Process Intensification of Metal Solvent Extraction Studies using a Miniaturized Solvent Extraction Plant”. ChemRxiv, 2023, pp. 26 DOI:https://doi.org/10.26434/chemrxiv-2023-nc9q1 DOI: https://doi.org/10.26434/chemrxiv-2023-nc9q1

P. Yudaev, E. Chistyakov. “Chelating Extractants for Metals”. Metals, vol. 12, no. 8, 2022. DOI: https://doi.org/10.3390/met12081275 DOI: https://doi.org/10.3390/met12081275

M. T. Collins, E. J. McConaghy, R. F. Stauffer, G. J. Desroches and B. D. Krysa, “Starting up the Sherritt Zinc Pressure Leach Process at Hudson Bay”, JOM, vol. 46, no. 4, pp. 51–58, 1994. DOI: https://doi:10.1007/bf03220675. DOI: https://doi.org/10.1007/BF03220675

E. Weidenhammer. Developments in Canadian Hydrometallurgy since 1950. Canada, Canada Science & Technology, 2021.

M. E. Chalkley, E. Ozberk and W. D. Vardill, “The treatment of bulk concentrates by the sherritt zinc pressure leach process”, Minerals Eng., vol. 6, no. 8-10, pp. 937–948, Aug. 1993. DOI: https://doi:10.1016/0892-6875(93)90066-v. DOI: https://doi.org/10.1016/0892-6875(93)90066-V

K.R Buban, M.J. Collins, and LM. Masters, "Iron control in zinc pressure leach processes" JOM, vol.51, no. 12, pp. 23-25, 1999. DOI: https://doi.org/10.1007/s11837-999-0166-8

“Zinc Applications Archives | ZINC. International Zinc Association”. Home | ZINC. International Zinc Association. Accessed: Jun. 2023. [Online]. Available: https://www.zinc.org/category/learning-annex/zinc-applications/

“Zinc: reservas mundiales por países 2022 | Statista”. Statista. Accessed: May 8, 2023. [Online]. Available: https://es.statista.com/estadisticas/635671/reservas-mundiales-de-zinc-por-paises/

A. Akcil, Z. Sun y S. Panda, “COVID-19 disruptions to tech-metals supply are a wake-up call”, Nature, vol. 587, n.º 7834, pp. 365–367, Nov. 2020. DOI: https://doi:10.1038/d41586-020-03190-8. DOI: https://doi.org/10.1038/d41586-020-03190-8

International Zinc Association, “Zinc Recycling Report 2050: Supply and Demand”. Accessed: May 14, 2023. [Online]. Available: www.zinc.org.

A. Siegmund, S. Alam, J. Grogan, U. Kerney and E. Shibata. Pb-9th International Symposium on Lead and Zinc Processing. The Minerals, Metals & Materials Series. Springer, 2020. DOI: https://doi:10.1007/978-3-030-37070-1 DOI: https://doi.org/10.1007/978-3-030-37070-1

C.M. Backman, “Global Supply and Demand of Metals in the Future”, J. Toxicol. Environmental Health, Part A, vol. 71, no. 18, pp. 1244–1253, Aug. 2008. DOI: https://doi:10.1080/15287390802209582. DOI: https://doi.org/10.1080/15287390802209582

L. Rostek, E. Pirard and A. Loibl, “The future availability of zinc: Potential contributions from recycling and necessary ones from mining”, Resources, Conservation & Recycling Advances, p. 200166, Jun. 2023. DOI: https://doi:10.1016/j.rcradv.2023.200166. DOI: https://doi.org/10.1016/j.rcradv.2023.200166

L. Rostek, L. Tercero Espinoza, D. Goldmann and A. Loibl, “A dynamic material flow analysis of the global anthropogenic zinc cycle: Providing a quantitative basis for circularity discussions”, Resources, Conservation Recycling, vol. 180, p. 106154, May 2022. DOI: https://doi:10.1016/j.resconrec.2022.106154. DOI: https://doi.org/10.1016/j.resconrec.2022.106154

“Mineral commodity summaries 2023”, US Geological Survey, 2023. DOI: https://doi:10.3133/mcs2023. DOI: https://doi.org/10.3133/mcs2023

K. Binnemans y P. T. Jones, “The Twelve Principles of Circular Hydrometallurgy”, J. Sustain. Metall., December 2022. DOI: https://doi:10.1007/s40831-022-00636-3. DOI: https://doi.org/10.1007/s40831-022-00636-3

L. H. Xavier, M. Ottoni y L. P. P. Abreu, “A comprehensive review of urban mining and the value recovery from e-waste materials”, Resources, Conservation Recycling, vol. 190, p. 106840, Mar. 2023. DOI: https://doi:10.1016/j.resconrec.2022.106840. DOI: https://doi.org/10.1016/j.resconrec.2022.106840

A. Arguillarena, M. Margallo,A. Arruti-Fernández, J. Pinedo, P. Gómez, I. Ortiz and A. Urtiaga, “Circular economy in hot-dip galvanizing with zinc and iron recovery from spent pickling acids”, RSC Advances, vol. 13, no. 10, pp. 6481–6489, 2023. DOI: https://doi:10.1039/d2ra08195d. DOI: https://doi.org/10.1039/D2RA08195D

Report on the Environmental Benefits of Recycling Bureau of International Recycling, 2016 https://www.bir.org/images/uploads/publications/BIR-CO2-report-2016-FIN-WEB.pdf

E. Rudnik, “Investigation of industrial waste materials for hydrometallurgical recovery of zinc”, Minerals Eng., vol. 139, p. 105871, Aug. 2019. DOI: https://doi:10.1016/j.mineng.2019.105871. DOI: https://doi.org/10.1016/j.mineng.2019.105871

M. Kaya, S. Hussaini, S. Kursunoğlu. Critical review on secondary zinc resources and their recycling technologies. Hydrometallurgy, 2020.105362. DOI: https://doi:10.1016/j.hydromet.2020.10536 DOI: https://doi.org/10.1016/j.hydromet.2020.105362

Z. Sun, Y. Xiao, H. Agterhuis, J. Sietsma, Y. Yang. “Recycling of metals from urban mines – a strategic evaluation”. Journal of Cleaner Production, vol. 112, part 4, pp. 2977-2987, 2015. DOI: https://doi:10.1016/j.jclepro.2015.10.116. DOI: https://doi.org/10.1016/j.jclepro.2015.10.116

C. Hageluken. “Recycling of electronic scrap at Umicore’s integrated metals smelter and refinery”. Proceedings of European Metallurgical Conference, vol. 59, pp. 307-323, 2005.

R. Rajesh, D. Kanakadhurga and N. Prabaharan, “Electronic waste: A critical assessment on the unimaginable growing pollutant, legislations and environmental impacts”, Environmental Challenges, vol. 7, p. 100507, Apr. 2022. DOI: https://doi:10.1016/j.envc.2022.100507. DOI: https://doi.org/10.1016/j.envc.2022.100507

S. M. Sadeghi, J. Jesus y H. M. V. M. Soares, “A critical updated review of the hydrometallurgical routes for recycling zinc and manganese from spent zinc-based batteries”, Waste Manage, vol. 113, pp. 342–350, Jul. 2020. DOI: https://doi:10.1016/j.wasman.2020.05.049. DOI: https://doi.org/10.1016/j.wasman.2020.05.049

N. Štrbac, I. Mihajlović, V. Andrić, Ž. Živković y A. Rosić, “Kinetic investigations of two processes for zinc recovery from zinc plant residue”, Can. Metallurgical Quart., vol. 50, no. 1, pp. 28–36, Jan. 2011. DOI: https://doi:10.1179/000844311x552287. DOI: https://doi.org/10.1179/000844311X552287

V. Forti, C. P. G. Balde, R. Kuehr y B. Garam, The Global E-waste Monitor 2020: Quantities, flows and the circular economy potential. Bonn/Geneva/Rotterdam: United Nations University (UNU)/United Nations Institute for Training and Research (UNITAR) – co-hosted SCYCLE Programme, International Telecommunication Union (ITU) & International Solid Waste Association (ISWA), 2020.

International Lead and Zinc Study Group, “The world zinc factbook 2024”. [Online]. Available: https://www.ilzsg.org/wpcontent/uploads/SitePDFs/The%20World%20Zinc%20Factbook%202024.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 EPISTEMUS

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

The magazine acquires the patrimonial rights of the articles only for diffusion without any purpose of profit, without diminishing the own rights of authorship.

The authors are the legitimate owners of the intellectual property rights of their respective articles, and in such quality, by sending their texts they express their desire to collaborate with the Epistemus Magazine, published biannually by the University of Sonora.

Therefore, freely, voluntarily and free of charge, once accepted the article for publication, they give their rights to the University of Sonora for the University of Sonora to edit, publish, distribute and make available through intranets, Internet or CD said work, without any limitation of form or time, as long as it is non-profit and with the express obligation to respect and mention the credit that corresponds to the authors in any use that is made of it.

It is understood that this authorization is not an assignment or transmission of any of your economic rights in favor of the said institution. The University of Sonora guarantees the right to reproduce the contribution by any means in which you are the author, subject to the credit being granted corresponding to the original publication of the contribution in Epistemus.

Unless otherwise indicated, all the contents of the electronic edition are distributed under a license for use and Creative Commons — Attribution-NonCommercial-ShareAlike 4.0 International — (CC BY-NC-SA 4.0) You can consult here the informative version and the legal text of the license. This circumstance must be expressly stated in this way when necessary.

The names and email addresses entered in this journal will be used exclusively for the purposes established in it and will not be provided to third parties or for their use for other purposes.